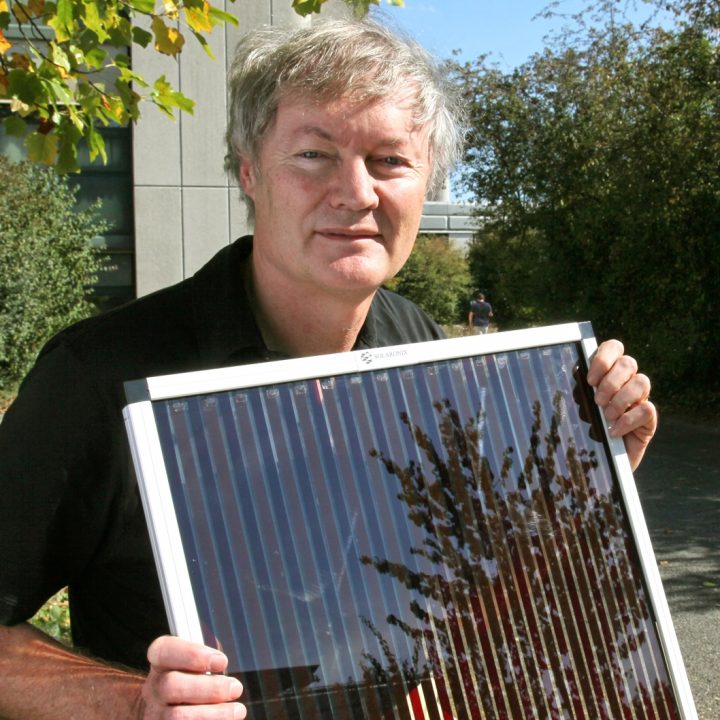

The 2010 Millennium Grand Prize Winner Michael Grätzel is the father of third generation dye-sensitized solar cells. Grätzel cells, which promise electricity-generating windows and low-cost solar panels, have just made their debut in consumer products.

One of mankind’s greatest challenges is to find ways to replace the diminishing fossil fuel supply. The most obvious energy source is the sun, origin of almost all the energy found on Earth. The surface of the Earth receives solar radiation energy at an average of 81,000 terawatt – exceeding the whole global energy demand by a factor of 5,000. Yet, we are still figuring out a cost-effective way of harnessing it.

Solar cells, converting energy from the sun into electricity, were first used in the 1950s to power orbiting satellites and other spacecraft. Applied to power generation on Earth, the price does matter. Selected silicon based technology was – and still is – expensive, even if the cost of photovoltaics has declined steadily since the first solar cells were manufactured.

Grätzel’s innovation, the dye solar cell (DSC), is a third generation photovoltaic technology. The technology often described as ‘artificial photosynthesis’ is a promising alternative to standard silicon photovoltaics. It is made of low-cost materials and does not need an elaborate apparatus to manufacture. Though DSC cells are still in relatively early stages of development, they show great promise as an inexpensive alternative to costly silicon solar cells and an attractive candidate for a new renewable energy source.

Read Michael Grätzel’s resent news

Read how 2010 Millennium technology Prize innovation is changing the way.

Read more about Millennium Technology Prize winners

Laureates

-

Plastic electronics

(Great Britain)

The 2010 Millennium Technology Prize Laureate Sir Richard Friend’s initial innovation, organic Light Emitting Diodes (LEDs), was a crucial milestone in plastic electronics. He showed a method to use polymers as solution processed semiconductors. Electronic paper, cheap organic solar cells and illuminating wall paper are examples of the revolutionary future products his work has made possible.In electronic devices different materials have different functions. Traditional electronics rely on inorganic conductors such as copper and doped silicon. Copper wires conduct electricity; silicon semiconductor chips do the computing. Polymer plastics are generally insulators, blocking the passage of electrical current. They are an excellent choice for around wires to prevent short circuits, or to shape mobile phone covers. Or so traditional thinking would suggest.

Today many new phones have touch OLED screens. OLED stands for Organic Light Emitting Diode, made of conductive plastic material. The material is called “organic” because the polymers used are carbon-based, much like living organisms. Soon we may see 100 inch high-definition TV-sets, which are only few millimetres thick and can be rolled up when not in use, or paper-thin, inexpensive lighting panels covering the whole wall. Electronic components based on polymers have made these applications possible.

Friend’s inventions were landmark achievements in the rise of plastic electronics. In the late Eighties, his research group discovered that conjugated polymers behave in many respects like inorganic semiconductors and can be used in a number of semiconducting devices. Realising the significance of their discovery Richard Friend, Donal Bradley and Jeremy Burroughes filed a patent for polymer LED in April 1990.

Thanks to their pioneering discoveries, plastic electronics has now developed into a large international research field with significant academic and industrial activities. Polymer LEDs are already used in small displays, and energy-efficient lighting applications are being developed. Polymer photovoltaic diodes promise to enable very low cost solar cells. Printed polymer transistors enable new electronic applications such as flexible and transparent displays.

An important characteristic of plastic electronics is the simplicity of the method used to produce them. Inorganic transistors require massive vacuum systems and complex manufacturing processes. However, the organic polymer materials Friend used can be dissolved in organic solvents to create “inks” that can be used to create circuits simply by printing them under normal atmospheric conditions.

It is easy to understand the global electronics industry’s huge interest in organic and solution processable semiconductor technology. The ability to apply low temperature, low cost transistors and LEDs to flexible materials using a process that could be as simple as painting can enable new products that, until now, were unfeasible.

-

ARM microprosessor

(Great Britain)

The 2010 Millennium Technology Prize laureate Steve Furber is the principal designer of the ARM 32-bit RISC microprocessor, an innovation that revolutionised mobile electronics. The ingeniously designed processor enabled the development of cheap, powerful handheld, battery-operated devices. In the past 25 years nearly 20 billion ARM based chips have been manufactured.You may never have heard of ARM microprocessors, but probably use at least one every day. They tick inside our mobile phones, mp3-players, video recorders and home routers. Today ARM technology is used in more than 98 percent of the world’s mobile handsets and over one-quarter of all electronic devices.

In 1985 Furber become the father of a microprocessor phenomenon – a single chip which did the same amount of work as other 32-bit microprocessors but used one tenth of their transistors – and consequently, one tenth of their electricity. Furber was the principal designer of the ARM 32 bit microprocessor at Acorn Computers.

The original design was simple and elegant. It exploited Reduced Instruction Set Computing (RISC) architecture. ARM was the world’s first commercially available RISC microprocessor. It was initially used in the Acorn Archimedes personal computer released in 1987.

The relative simplicity of ARM processors made them suitable for low power applications. It is this that has allowed them to dominate the mobile and embedded electronics market as relatively low cost and small microprocessors and microcontrollers.

Furber’s innovation has underpinned the rapid growth in mobile communications, which has opened up economic opportunities and enhanced the quality of life for billions in the developing and developed world.

Today about 98 percent of the more than one billion mobile phones sold each year use at least one ARM processor. The processors are also used extensively in other consumer electronics, including PDAs, digital media and music players, hand-held game consoles, calculators and computer peripherals such as hard drives and routers.